Extruded plastic netting represent an advanced technology in the production of screens for various applications. Through an extrusion process, plastic is molded into specific profiles, creating a lightweight, strong, and versatile structure.

Advantages over other materials:

Width: 1,00m, 1,50m and 2,00m

Color: Green | Black

Mesh Opening: 22mm and 25mm depending on the model

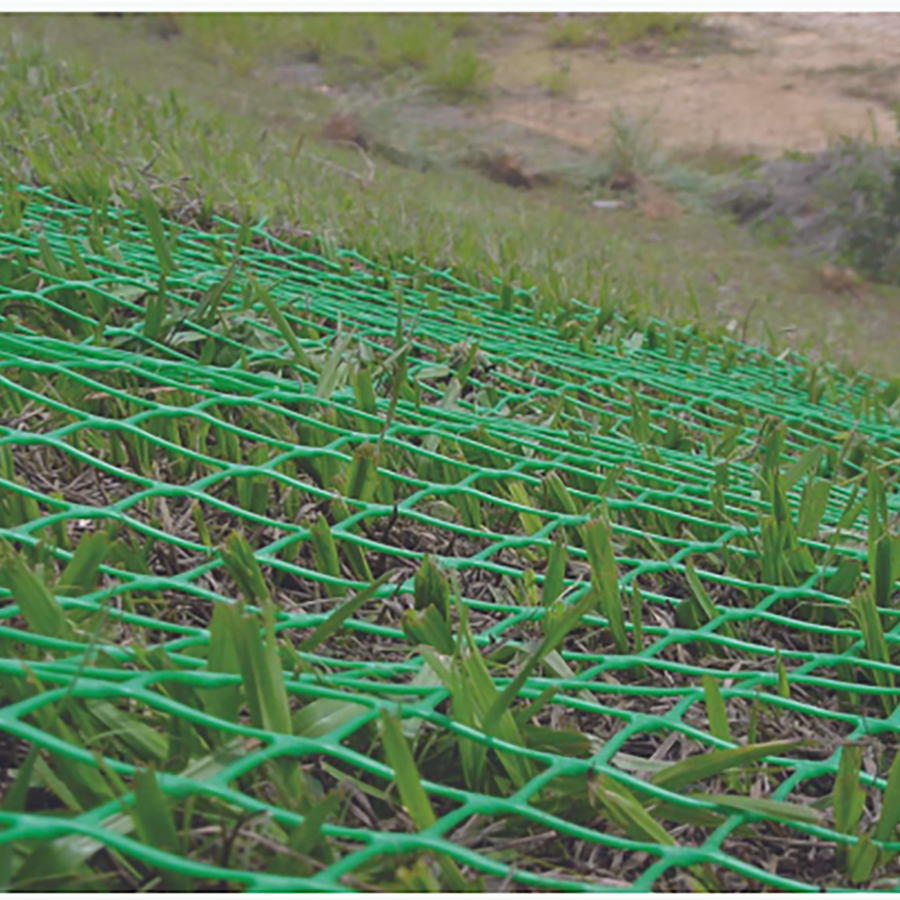

Applications: For erodible soils and steep slopes, a vegetated geosynthetic erosion control system is recommended, which promotes plant establishment by providing a stable growth medium and facilitates the development of a self-reinforcing, uniform vegetative cover that protects the slope from erosion.

We offer a complete line of Plastic Screens and Tarpaulins, with production technology in Extrusion, Weaving and “Blow Film” Extrusion. Ideal to serve the most varied segments and uses.